JC-Magazine

JC-Electronics launches quality mark for refurbished industrial electronics

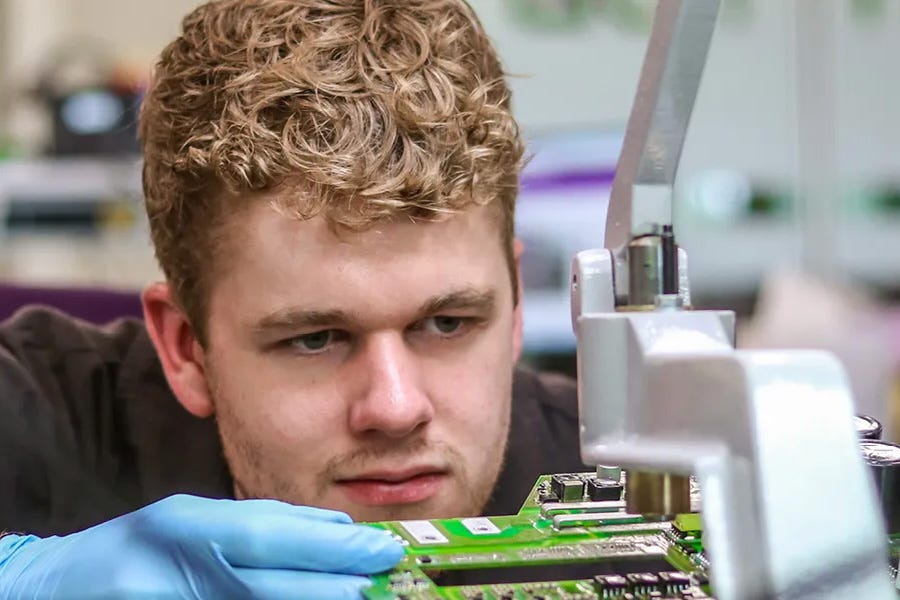

JC-Electronics launches JCertified, a quality mark for refurbished industrial electronics. With this, the electronics company responds to the overstrained situation in the market for drives, HMIs, PLCs and industrial PCs. JC-Electronics wants to give the manufacturing industry confidence in refurbished electronics with its quality mark.

Second life for OP7s thanks to laser

Thanks to laser technology, we repair more Siemens OP7 HMIs and have a larger stock.

Schneider Electric and our focus on delivering industrial electronics

A breakdown means decline. So when a production line stalls, the factory has to be up and running again, as soon as possible. That is why we invest heavily in the availability of industrial electronics.

Market prices of electronics keep rising

We understand how higher market prices can lead to frustration. That's why we explain why prices are higher and we help you save, where possible.

A sign of the times?

The prices and delivery times of industrial electronics rose sharply in 2021. COVID caused a significant increase in the demand for consumer electronics, creating a high demand for bulk materials.

Have your industrial PC custom configured

When the manufacturer no longer supports its products or drastically reduces its service, you can count on JC-Electronics.

Customer Statement: Prysmian Group

"To our surprise, we realized we didn't have an extra analog input card in stock. We contacted JC-Electronics, asking if they had this card in stock."

Best quality Siemens HMIs from stock

HMI products are used intensively. At JC-Electronics we test, repair and overhaul many types of HMIs and also have a large number of different HMIs in stock.

2-year warranty on all products

We are proud to announce that we offer a full 2-year warranty on all new & refurbished stock items and repairs.

Groningen business conquers the world with used electronics

Read the success story of JC-Electronics here. It started off in an attic room but nowadays JC-Electronics has grown to a multinational company.